Van Hattum en Blankevoort

Better in Control

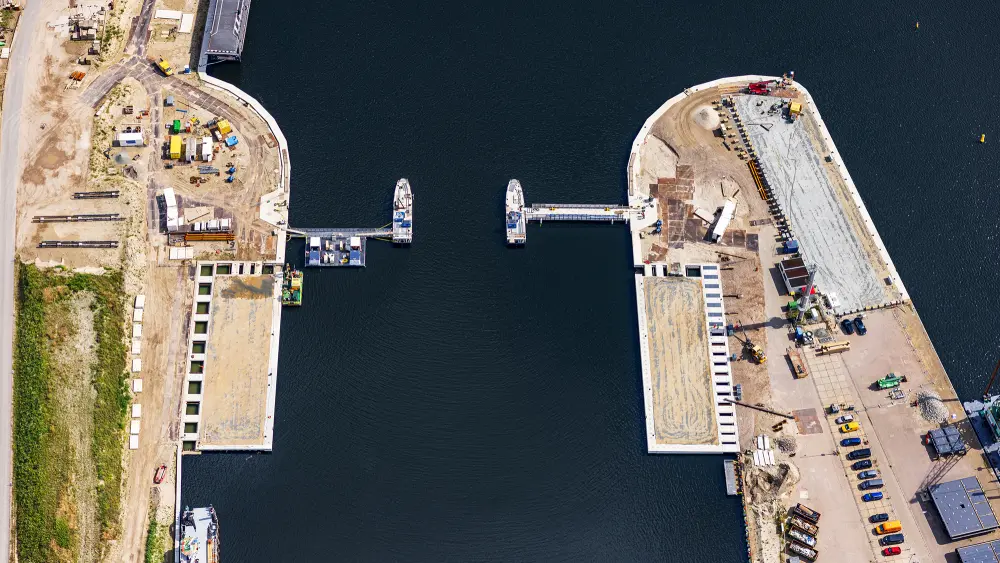

Van Hattum en Blankevoort designs, builds, and maintains civil structures for the infrastructure, energy, and real estate markets. It focuses on structures in traffic infrastructure, on projects on and in the water, and in the ground. Van Hattum en Blankevoort operates with technical creativity and is strong in broad project management. Van Hattum en Blankevoort continuously has improving its organization on the agenda. It demonstrates entrepreneurship, is results-oriented, and emphasizes collaboration. “We realize projects by planning and organizing well, which enables us to keep costs as low as possible.” Safety, health, and environment are high priorities, with a focus on customers and surroundings. Van Hattum en Blankevoort is aware of its responsibility toward society.

The end of the RAW specification system

The business environment in construction is constantly subject to changes. To deal with these changes, an organization must be flexible. Van Hattum en Blankevoort also experienced this firsthand. In 2004, its clients decided to move away from the traditional RAW specification system. It primarily meant that Van Hattum en Blankevoort previously executed what the client conceived and prescribed, and nowadays is also responsible for design, realization, and maintenance, which also includes environmental and process management. Hans Berkien is QEH Manager at Van Hattum en Blankevoort and he encountered this. The different system required a different approach within the organization—there was more difficult collaboration and communication had to be done differently. Hans Berkien experienced major challenges particularly in the preliminary phase of each project: “Many stakeholders had to work together and reach agreement. That sometimes proceeded inefficiently, often resulting in misunderstanding, duplicate agreements, and consequently also poorer results.” This pressing situation was the reason to examine the organization and reshape and reorganize the primary processes.

Management and maintenance

Van Hattum en Blankevoort had to align with the new market situation, which meant the organization had to be restructured. Hans Berkien felt that a solid process and quality management system was necessary to achieve the restructuring. He believed that with the existing management system, the intended result could not be achieved sufficiently efficiently: “We used separate Word and Excel documents. Within the old document-based system, there was a possibility to work with hyperlinks, but then an entire structure had to be built each time, which requires a lot of time and attention. It was a kind of matrix into which every document and process could be placed—a fairly simple and flat way. In addition, changes in the relevant documents meant that the links suddenly disappeared and you could start over again. The management and maintenance of this management environment was very labor-intensive. Furthermore, the working method at the time offered no solution to the restructuring problem.”

<h2″>Looking for a solution

<p”>It was high time for change. Hans Berkien went looking for a method and package that would offer a solution to this situation. Through a consultancy firm, he came into contact with three packages. One was immediately eliminated given the price and complexity. He then ran the two packages in parallel within the organization, after which Manual Master was chosen: “We chose it then because it was simple to implement our Word documents within the system. At that moment, that was the best choice.” However, Hans Berkien experienced the same problem as before—a lack of ease of use when building and little consistency on the existing ICT platform. This caused, on the one hand, a lot of freedom within the system allowing all kinds of processes and drawings to be made, but on the other hand, extra work.

<p”>Hans Berkien: “The purchase of the system was a step forward, but it didn’t offer a solution to the restructuring problem. In addition, a need arose to look increasingly critically at processes for larger projects.”

<h2″>The right solution

<p”>Again, it was discussed whether the choice would now fall on Comm’ant or on a completely different system. Hans Berkien had test-driven Comm’ant during the previous selection process. After the choice fell on Manual Master, he had continued the trial with a select group of employees. He found it very pleasant and useful to work with: “With a group of 15 people, we then built a business operations system in Comm’ant for one business unit. We could very quickly set up a system with a reliable structure from scratch. It was a matter of simply filling in boxes. The advantage is that you’re really working on the content.

<p”>Comm’ant is also based on an output-oriented process model, which ensures that you automatically focus on the end result. This prevents you from drifting off and being busy with unnecessary details in diagrams. Moreover, we sailed through ISO certification! Our choice therefore ultimately fell convincingly on Comm’ant.”

A pleasant implementation

Comm’ant was already implemented within one business unit. Subsequently, Comm’ant was gradually rolled out per business unit. Hans Berkien is currently the administrator of the business operations system—he experienced the implementation as positive: “We set up the business operations system by, among other things, identifying and linking processes, inputs and outputs of those processes, roles, functions, responsibilities, and authorities in Comm’ant. In addition, we placed work instructions in the right places in the system, which also creates real substantive functions and roles. The whole process went remarkably smoothly.” Employee involvement is crucial in this phase. If no one spends time and attention on implementation, the system will not only show deficiencies but ultimately won’t be used either. MyComm’ant supports the desired behavior.

It provides personal function-oriented information—you see the system, as it were, from the I-perspective. You have an immediate overview of My processes, My tasks, responsibilities and authorities, My documents, etc.:

“During the system trainings, we immediately saw that employees enjoy experiencing the system from their role in the organization. You see that they then want to go the extra mile and share their knowledge to optimize not only the system but especially the insight and collaboration.”

Simplicity through logical coherence

The organization has been using Comm’ant for nine years now. A reason for this long-term agreement is the user-friendliness of the package. Many providers of process and quality management systems claim that their tools are easy to use, but in practice this doesn’t always turn out to be the case. Hans Berkien does experience the accessibility of the Comm’ant system: “Because the logic is integrated into the system in such a way, you are, as it were, forced to work in the right way. The number of levels, processes, and connections are kept limited in a logical way. Of course, you can supplement the whole with pictures, documents, and videos, but the building blocks remain coherent. With the help of business units, you can make access even more specific.”

Flexible but consistent

Comm’ant’s system is based on logical coherence. As a result, the system is fully automatically consistent. This means that the system with all its links and connections is not affected when something is changed. Even during intensive use of the system, such as searching and consulting processes with many people, requesting documents, etc., the system continues to work solidly. This means that developers can also work and make changes ‘live’ in the system with confidence, without fear of harmful actions. Hans Berkien further notes that creating and adjusting process structures proceeds without problems:

“The advantage of a consistent system like Comm’ant is that you immediately see the loose ends. If you have a database for a particular model, you only have to connect the loose ends and you have a well-running process.”

Projects ‘in control’

It was mentioned earlier that the organization’s projects didn’t run so smoothly and that this manifested itself in a less satisfactory end result. Hans Berkien noticed a clear change in working method after the processes were reset in Comm’ant:

“Through Comm’ant, we gained more insight, and this led to better work agreements and behavior. Comm’ant has been a good tool in this and still is.”

Knowledge preservation

Comm’ant can be compared to a coat rack on which you hang all kinds of information. When it turns out that something isn’t working properly or that there’s an exceptional situation, additional knowledge is hung on the process coat rack. This way, you develop increasingly smarter and more profitable business operations with a kind of collective memory. That’s very important because employees come and go, and the knowledge remains within the organization. In addition, it forms a basis for training new employees with function-related information. Hans Berkien notes that new employees pick up the thread faster through Comm’ant: “When a new employee enters the company, we first have them look in the business operations system. This way, the employee immediately has a good picture of their role within the organization and it also prevents the wheel from having to be reinvented over and over. A helping hand is that Comm’ant has a very good search function. This search function can even search within documents—ideal!”

Collaboration

Hans Berkien indicates that he experiences Comm’ant’s service as good: “I never have complaints about it. It doesn’t matter whether you send an email or call—you get help within a very short time, and everything is done to resolve the issue. A pleasant collaboration!”